Introduction

The manufacturing industry is always looking for new ways to innovate and improve. And right now, they’re really excited about Artificial Intelligence (AI). AI is changing the way products are designed, made, and delivered. In this article, we’ll take a closer look at how AI is being used in manufacturing, and what the future holds for this exciting technology.

We’ll explore the wide range of applications for AI in manufacturing, the many benefits it offers, and the exciting possibilities it holds for the future. We’ll also discuss how businesses can strategically harness AI’s capabilities to improve productivity and competitiveness.

So sit back, relax, and let’s take a look at the future of manufacturing with AI!

AI in manufacturing

In manufacturing, AI has emerged as a catalyst for innovation, automating processes, making intelligent decisions, and enhancing operational efficiency.

According to a survey, The AI market within the manufacturing sector is projected to experience a remarkable Compound Annual Growth Rate (CAGR) of 57%, surging from $1.1 billion in 2020 to $16.7 billion by 2026.

This substantial expansion can be primarily attributed to the ready availability of extensive datasets, a rising trend in industrial automation, enhancements in computational capabilities, and substantial increases in capital investments.

Furthermore, as per a Deloitte survey, the manufacturing sector stands out as the leading industry in terms of data generation. Consequently, manufacturers will be compelled to embrace AI for the analysis of this immense volume of data generated within the sector.

Here are some key areas where AI in manufacturing industry is making a significant impact

Applications of AI in Manufacturing Industry

AI is totally changing the manufacturing game. Here are 6 ways it’s being used to improve efficiency and quality:

Predictive Maintenance

AI in manufacturing is changing the game with predictive maintenance. By using smart analytics and machine learning AI can analyze data from sensors and machinery to predict when equipment is likely to fail.

This proactive approach reduces downtime, extends the lifespan of machinery, and lowers maintenance costs, allowing factories to boost productivity while lowering repair bills.

In predictive maintenance, an important idea is the “digital twin.” which is a virtual copy of your machine, to collect data and spot potential problems before they happen. This way, you can take action to fix them before they cause a breakdown, which can save you a lot of time and money.

Quality Assurance

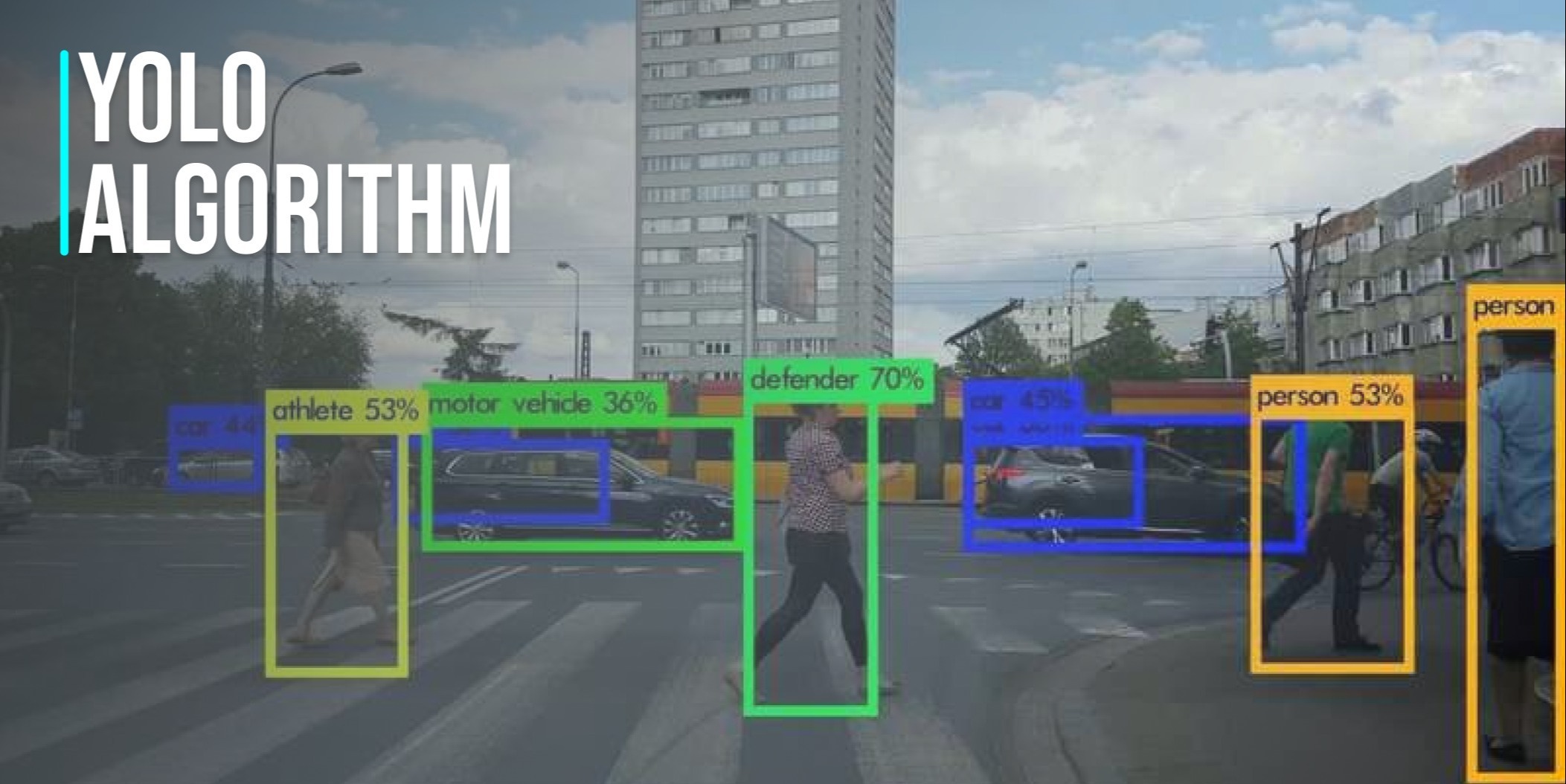

Quality control is vital in manufacturing, and artificial intelligence is transforming how it’s done. Companies are using AI and machine learning to enhance their quality assurance, making it more precise and consistent.

AI-driven vision systems can detect defects and anomalies in real-time, ensuring that only products meeting strict quality standards make it to the market.

BMW uses AI to check car parts for problems. They do this by teaching a computer program to look at pictures and videos of parts. The program learns from a set of labeled images showing which parts are faulty and which are not. After training, the AI can be used to inspect new parts and find any issues.

Demand Prediction

AI is a lifesaver for manufacturers. It can predict demand by looking at past sales, market trends, and other factors. This helps companies make smart decisions about how much to produce and when.

For example, let’s say a fashion company uses AI to forecast how much of each clothing item people will want. The AI looks at data from social media, weather predictions, and customer preferences. This helps the store keep the right amount of each item in stock, so they don’t have too much or too little inventory.

Factory automation

Factory automation has gotten a major upgrade with the integration of artificial intelligence in manufacturing. AI and ML have turned factories upside down in terms of efficiency, productivity, and cost-effectiveness.

AI-powered robots equipped with computer vision and machine learning algorithms can perform complex tasks with precision and adaptability. These robots can handle intricate assembly processes, quality control inspections, and even collaborate with human workers in a seamless manner

For example, Whirlpool, with a 3.6% stake, is one of the companies employing Robotic Process Automation (RPA) in manufacturing. They utilize this technology to automate their assembly line operations and manage materials. Additionally, they employ bots for conducting quality control checks.

Process Optimization

AI-powered software is a valuable asset for companies striving to achieve sustainable production levels by streamlining their operations. Manufacturers can leverage AI-driven process analysis tools to identify and eliminate bottlenecks in their processes, enhancing efficiency.

Moreover, AI’s ability to fine-tune production processes by adjusting variables like temperature and pressure not only maximizes output but also minimizes waste, resulting in substantial cost savings and resource efficiency.

For instance, a manufacturer used a process analysis tool in their procurement and payment procedures. This led to a reduction in discrepancies and unauthorized purchases by $60,000. Additionally, the company found ways to automate invoicing tasks by 75%.

Supply Chain Management

Supply chain management plays a crucial role in the manufacturing industry, and artificial intelligence has emerged as a game changer in this field. By harnessing the power of AI and ML in manufacturing, companies are revolutionizing their supply chain processes and achieving significant improvements in efficiency, accuracy, and cost-effectiveness.

AI optimizes inventory management, demand forecasting, and route planning, resulting in reduced inventory holding costs and improved delivery efficiency. Manufacturers can respond more swiftly to market fluctuations, improving customer satisfaction.

These are just a few of the ways AI is transforming manufacturing. As AI technology continues to develop, we can expect even more innovative and groundbreaking applications in this field.

Top Benefits of AI in Manufacturing

The incorporation of AI in manufacturing brings forth a multitude of benefits that transform the landscape for businesses. Some of these advantages include:

Increased Productivity

AI-driven automation minimizes human errors and accelerates production, leading to increased operational efficiency and output.

It can herpes manufacturer save their time from repetitive tasks allowing them to focus on new and creative things increasing their productivity and enhancing creativity.

This technology boosts employee productivity by providing easy access to crucial insights. Engineers can quickly find suitable materials for specific products, and manufacturers can use reports to predict orders.

Enhanced Safety

AI can monitor safety conditions in real-time, mitigating the risk of accidents and injuries in manufacturing facilities. This not only protects the workforce but also reduces liability and its associated costs.

According to the U.S. Department of Energy data, predictive maintenance can reduce machinery downtime by 35% to 45%.

Improved Quality

AI enables 360 degrees visibility across factories and manufacturing plants, lines, and warehouses, helping users detect quality issues, reduce scrap, and improve production.

AI-enabled quality control ensures the consistency and quality of products, reducing defects and customer complaints. This, in turn, enhances brand reputation and customer loyalty.

Manufacturers can increase production throughput by 20% and improve quality by as much as 35% with AI.

Better Decision Making

AI algorithms can analyze vast amounts of data to provide valuable insights. This data-driven decision-making process assists manufacturers in optimizing their operations and adapting to market changes effectively.

Real-World Examples of AI in Manufacturing

General Electric

General Electric engineers have used AI technology to create tools that could make designing jet engines and power turbines much faster.

General Electric (GE) uses AI to monitor the health of its aircraft engines and industrial equipment. This helps speed up the creation of the company’s next generation of products.

Foxconn

As a major manufacturer of electronic products, Foxconn uses AI-powered vision systems for quality control and inspection. These systems help identify defects and ensure the production of high-quality electronics.

Tesla

Tesla, the electric vehicle manufacturer, uses AI for various aspects of manufacturing. Their use of AI-powered robots in their factories is well-known, and AI is also integrated into their vehicles for features like self-driving capabilities.

Fanuc

Fanuc is a leading robotics and automation company that incorporates AI into its robotic systems. Their robots use AI to perform tasks with precision and adapt to changing conditions in manufacturing environments.

Future of AI in manufacturing

The future of AI in manufacturing holds tremendous potential for further innovation and efficiency.

AI is going to be huge in manufacturing. As the technology continues to improve, AI will be used in more and more ways to improve efficiency and quality.

For example, AI can be used to automate tasks that are currently done by humans, such as inspecting products for defects.

By strategically implementing AI in your business and staying at the forefront of technological advancements, you can ensure your manufacturing operations remain competitive and thrive in this rapidly evolving landscape.

How you can use AI in your business

Start by identifying your goals and specific ways in which AI can help you, whether it is for automating repetitive tasks, enhancing operational efficiency, or introducing RPA. Once your goals are clear, you can select an AI tool.

Create a personalized tool

AI can help you with automating repetitive tasks, improve quality control, and gain a competitive edge. You can look for custom AI tools to meet your needs.

You can also create a customized tool to meet the needs and goals

Consult a specific vendor

You should consult with a specialized AI vendor with whom you can define your goals for designing AI-powered tools for your niche. They can build personalized AI-powered tools for you based on your idea.

Conclusion

The integration of Artificial Intelligence in manufacturing marks a significant milestone in the evolution of the industry.

AI in manufacturing is like having a super helper that makes everything run smoother and better. It’s bringing more things, saving money, and keeping people safe

The benefits of AI in manufacturing are vast, and the only limit is our imagination in leveraging this transformative technology to propel the industry into a new era of excellence.

Do you want to create AI-enabled solutions for your company?

Please contact us now

We are an award-winning technology firm with extensive expertise in creating spectacular digital success stories for a wide range of businesses.

Let’s speak about it and join the wave of innovation